Steam hose is used for the hot water and saturated steam transfer during below application, such as coolant hose of cooling equipment, cold and hot water of engine, food processing industry, especially dairy factory. Steam hose can be applied to acid-base environment, but only in low concentrations. Steam hose can be divided into two kinds, that is low pressure steam hose and high pressure steam hose. For low pressure steam hose, its max working pressure can be 0.6 MPA, and temperature to be 164℃. And as for high pressure steam hose, its max working pressure can be high to 1.8MPA, and working temperature to be 210℃. Steam hose also can be sorted with oil resistance type and non-oil resistance type.

Structure

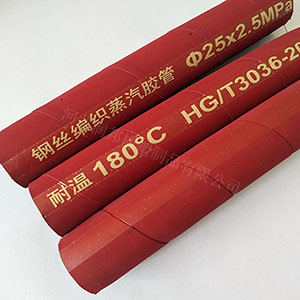

The structure of steam hose is the same with ordinary industrial hose, it consists of 3 parts, that is inner rubber layer, outer rubber layer and medium stainless steel wire braid.

The material of steam hose is always adopted with high quality EPDM rubber, EPDM rubber is high temperature resistance, high temperature steam resistance, Ozone and UV resistant and chemical resistance. The inner medium reinforcement layer always be fiber wire or stainless steel wire, its function is to strengthen the pressure bearing capacity of the steam rubber hose. The function of inner and outer rubber layer is to protect the stainless steel wire from corrosion, and steel wire is the skeleton structure to strengthen the working pressure.

Advantage

Character

Pressure: common working pressure is within 7 bar, and max working pressure can be high to 17 bar

Temperature: ordinary working range is from -40 ℃ to +208 ℃.

Resistance: common resistance coefficient is less than 109Ω.

Table 1 Physical Properties of Rubber Material

Performance

Unit

Requirement

Test Method

tensile strength (minimum)

Mpa

inner layer

outer layer

GB/T 528

elongation at break (minimum)

%

8

8

GB/T 528

change in tensile strength after aging (maximum)

%

50

50

GB/T 3512

change in elongation at break after aging (maximum)

%

50

carbon black filled compounds (max)

mm³

-----

200

GB/T 9867-2008

non-carbon black filled compounds (max, pigmented)

mm³

-----

400

volume change (max)

%

-----

100

GB/T 1690

Table 2 Physical Properties of Hose Assembly

Ω

Ω

Ω

≤10²/M型组合件

≤106/组合件

≤109/Ω型内衬层与外覆层间电阻

GB/T 9572-2001 方法4

GB/T 9572-2001 方法 3.4, 3.5 或3.6

Performance

Unit

Requirement

Test Method

Flexible Hose

Burst Pressure (minimum)

Mpa

10 times the maximum working pressure

GB/T 5563

Verification Pressure

Mpa

no leakage or distortion at 5 times the maximum working pressure

GB/T 5563

Interlayer Bonding Strength (minimum)

kN/m

2.4

GB/T 14905

Bending Test (without pressure, minimum)

T/D

0.8

ISO 1746

Verify Length Change under Pressure

%

-3~+8

GB/T 5563

Torque under Proof Pressure (max)

(º)/m

10

GB/T 5563

Ozone Resistance of Outer Layer

----

no visible cracks when magnified 2x

GB/T 24134-2009 中方法3,相对湿度(55±10)%,臭氧浓度(50±5)*10-9,伸长率20%, 湿度40℃

Hose Assemblies

Verification Pressure

Mpa

no leakage or distortion at 5 times the maximum working pressure

GB/T 5563

Resistance

Short-term Steam Test

----

第10章

第10章

Long term Steam Test

----

第10章

第10章

Part No.

Inner Diameter

Outer Diameter

Working Pressure

Burst Pressure

Weight

mm

inch

mm

bar

psi

mpa

bar

psi

mpa

kg/m

QTSH-1

13

1/2

25

17

250

1.7

51

750

5.1

0.53

QTSH-2

19

3/4

32

17

250

1.7

51

750

5.1

0.68

QTSH-3

25

1

39

17

250

1.7

51

750

5.1

0.9

QTSH-4

32

1-1/4

46

17

250

1.7

51

750

5.1

1.3

QTSH-5

38

1-1/2

54

17

250

1.7

51

750

5.1

1.6

QTSH-6

51

2

67

17

250

1.7

51

750

5.1

2.2

QTSH-7

63

2-1/2

83

17

250

1.7

51

750

5.1

3.8

QTSH-8

76

3

95

17

250

1.7

51

750

5.1

4.6

QTSH-9

102

4

124

17

250

1.751

51

750

5.1

6.5